Under the wave of Industry 4.0, "intelligence" can not only improve production efficiency but also provide technical guarantees for work safety. Line B of the intelligent workshop of Yongkang Bomo Fitness Equipment Co., Ltd. has achieved the dual goals of "work safety" and "efficiency improvement" by virtue of its advanced intelligent management system, becoming a "model production line" of the factory.

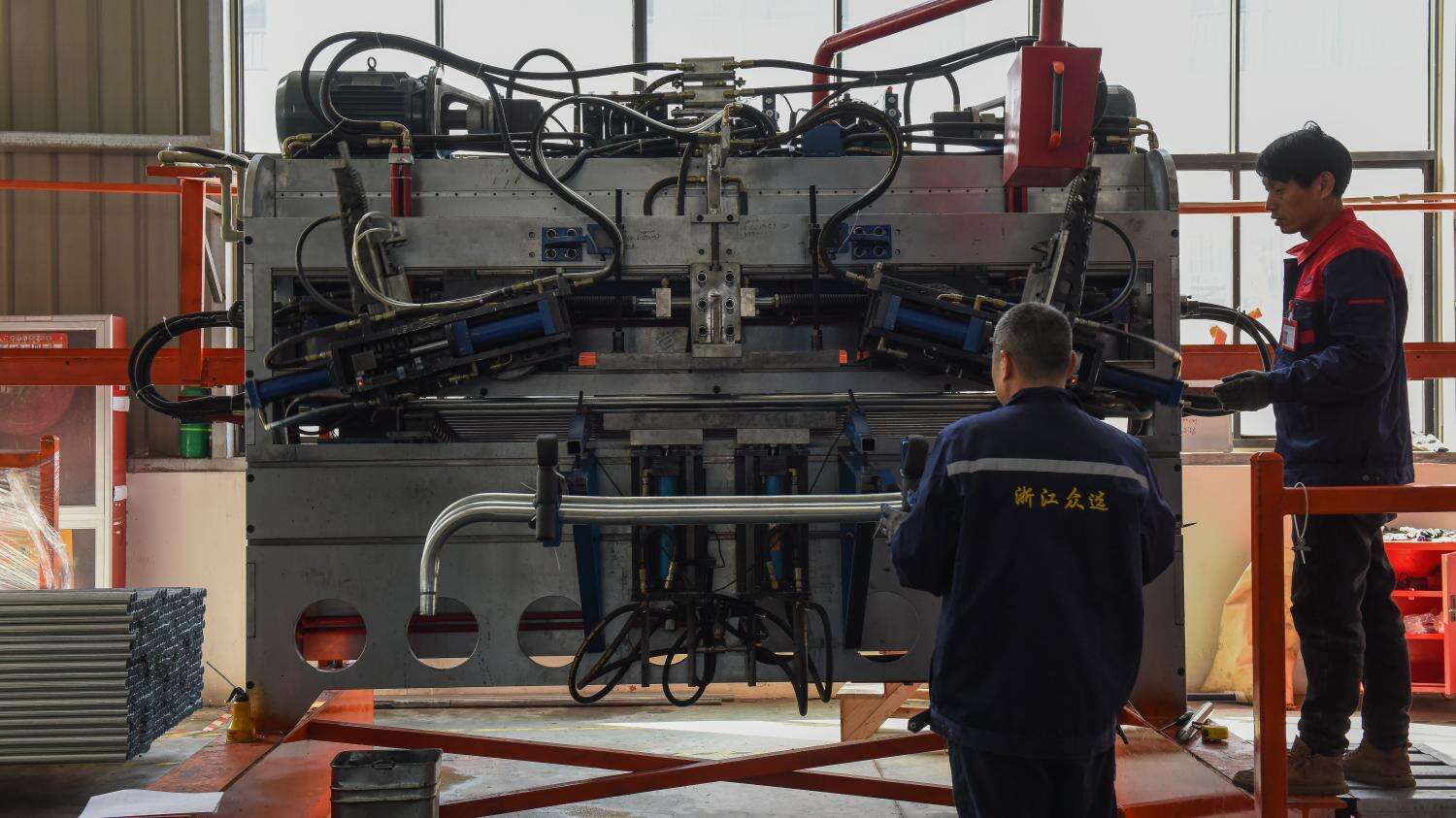

Intelligent Workshop Line B is mainly responsible for the processing and assembly of trampoline frames, equipped with 360-degree automatic welding machines, automatic feeding systems, and intelligent monitoring devices: automatic welding machines can replace manual labor to complete high-risk welding operations, reducing employees’ exposure to high temperatures and strong light; intelligent monitoring devices can real-time detect equipment operating status, and immediately shut down automatically and alarm once abnormalities occur (e.g., unstable voltage, loose parts), avoiding safety accidents caused by equipment failures. The workshop director said: "After intelligent transformation, not only has production efficiency increased by 30%, but the operational safety of employees has also been significantly improved, truly achieving a ‘win-win for safety and efficiency’."